- News class

- Contact us

-

Person:Mr Huang

Person:Mr Huang

Tel:0769-86846066

Fax:0769-87883862

E-mail:980831328@qq.com

Address:125 Tangqing West Road, Shitan Pu, Tangxia Town, Dongguan City

-

Film forming speed of aluminum profile

Release time:2024/2/27 15:25:32 | Source of information:东莞市南美铝业有限公司The difference of surface color of different types of aluminum profiles after conductive chemical conversion treatment is more obvious than that of oxide films obtained due to different process formulas. High aluminum purity and slow film-forming speed; If the purity of aluminum is low, the opposite is true. Therefore, it is necessary to master different parameters according to different aluminum profiles during oxidation. In order to achieve this, different types of aluminum sections are not allowed to be bound in the same string, so as not to control their appropriate oxidation time.

The advantages and disadvantages of aluminum profile composition can be distinguished during alkali etching. If there are too many gray black films or red films on the surface of the workpiece after alkali etching, it must be aluminum with high silicon or copper content. The chemical conversion time of this aluminum should be shortened, otherwise the obtained film will not meet the conductivity requirements.

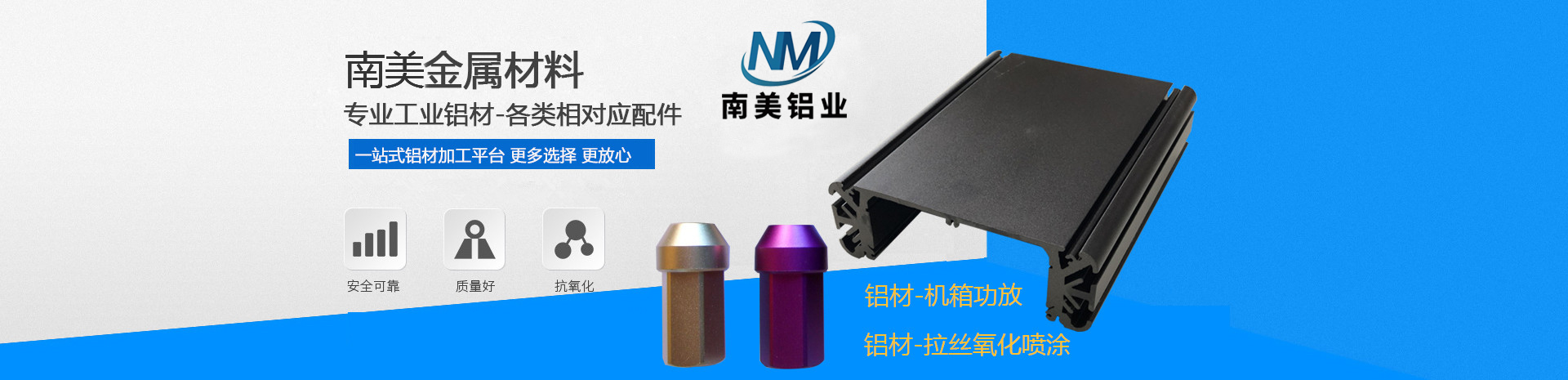

Dongguan South America Aluminum Co., Ltd. (Huang Sheng 13249985858) is a high-quality Dongguan industrial aluminum manufacturer. It mainly produces various high-quality and precision industrial aluminum profiles, polished aluminum, aluminum tubes, aluminum rods, aluminum plates, capillaries, etc. its main brands include 6063, 6061, 6463, 6262, 6n01, 6082, 6060, 2011, 2017, 2024, 7005, 7075, 1070, 5052, 5056, etc. Welcome to inquire

In the previous:Introduction to industrial aluminum profilesThe next article:Industrial aluminum production process